Common Types of A...

Dec 03, 2025

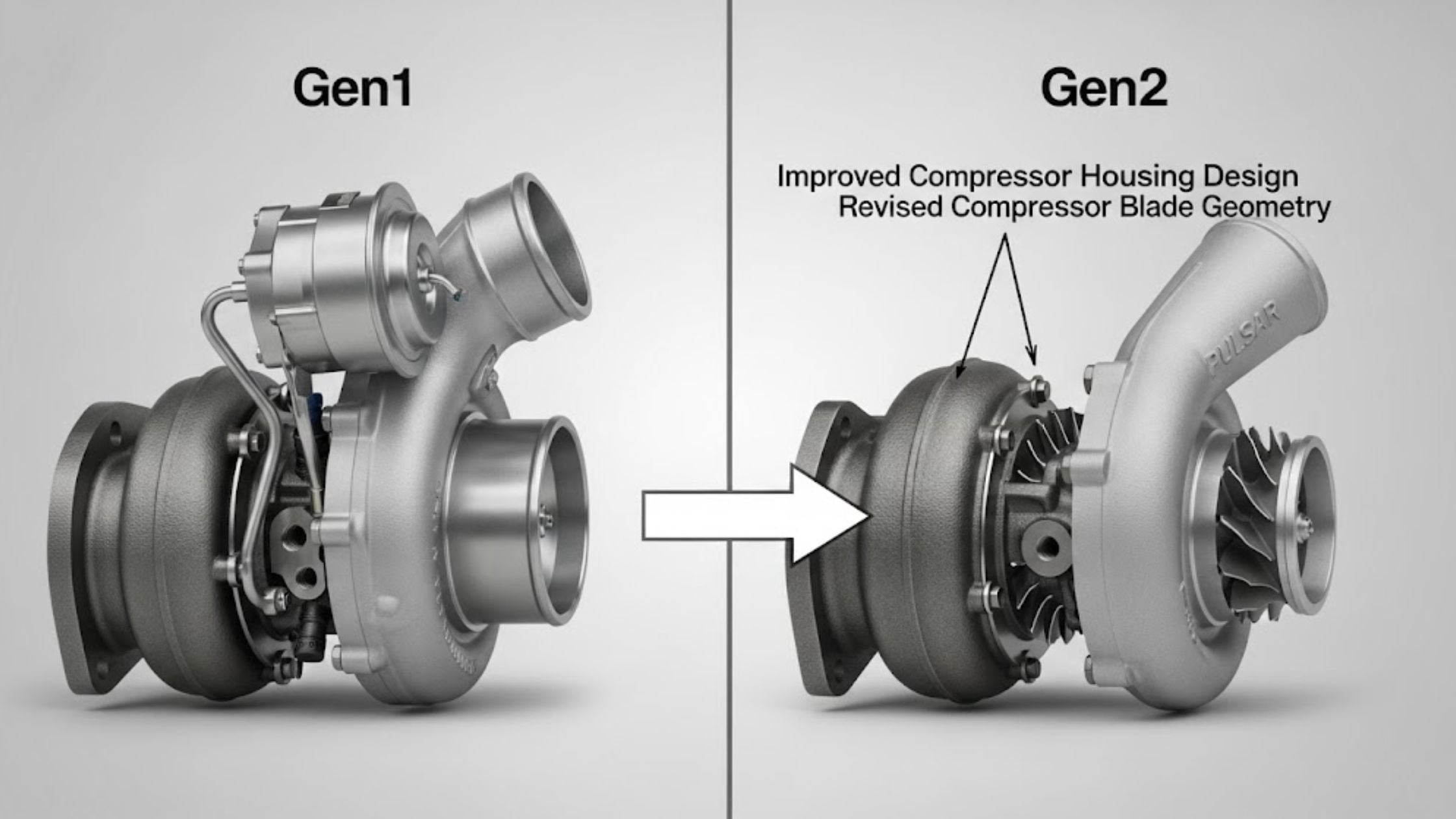

For automotive enthusiasts, the choice of turbocharger is crucial—it shapes the vehicle's response, power, and reliability. The transition from Pulsar Gen1 to Gen2 represents a significant advancement in turbocharger technology. This guide delves into the standout features of Gen1, the groundbreaking innovations of Gen2, and offers a side-by-side comparison of their core components. We’ll also explore the decision-making process for upgrading and how QuickBitz supports Pulsar installations and tuning across Australia. Expect to gain practical insights into bearing systems, compressor wheel design, performance metrics, cost-benefit analysis, and local service expertise—all in one comprehensive guide.

The Pulsar Gen1 turbocharger laid a strong foundation for high-performance forced induction, combining a reliable journal bearing system with a cast compressor wheel. This setup ensures stable operation and predictable boost characteristics, ideal for stock and mildly tuned conditions. Its robust design supports up to 500 hp with standard spool time and dependable durability.

Gen1’s core features include:

Journal Bearing TechnologyJournal bearings utilize an oil film between the shaft and bearing housing to minimize friction. This system ensures smooth operation under moderate boost pressures and offers straightforward maintenance routines.

Cast Compressor Wheel DesignThe cast aluminum compressor wheel features broad vane geometry, ensuring consistent airflow at mid-range RPMs. While heavier than billet, the wheel provides reliable performance and cost-effective manufacturing.

Performance MetricsPulsar Gen1 turbos typically achieve full boost in 1.2–1.4 seconds at 1 bar, supporting 300–500 hp setups. Efficiency peaks around 68–72 percent in the mid-flow range, balancing spool with flow capacity.

Durability and ReliabilityGen1’s simpler construction and fewer precision parts translate to lower rebuild costs and long service intervals. Regular oil changes and bearing inspections extend operational life beyond 100,000 km.

These foundational characteristics set the stage for Gen2’s advanced innovations, enhancing responsiveness, power potential, and longevity.

Pulsar Gen1 turbos employ a journal bearing system, where a pressurized oil film separates the rotating shaft from the bearing journal. This design reduces mechanical wear and supports sustained boost levels, making it ideal for stock-replacement setups. The oil film also cushions the shaft, smoothing high-RPM spinning and extending maintenance intervals.

Journal bearings, used in the Pulsar Gen1 turbochargers, rely on an oil film to reduce friction between the shaft and bearing housing, providing smooth operation under moderate boost pressures. This design is a common and cost-effective solution in many turbocharger applications, offering straightforward maintenance.

Related Blog: Are Pulsar Turbos a Good Option for Performance Builds in Australia?

The cast compressor wheel in Gen1 features broad, shallow vanes optimized for mid-range airflow. Cast from high-strength aluminum alloy, it balances manufacturing cost with consistent volumetric flow. Its heavier inertia yields predictable boost curves, though it spools marginally slower than billet counterparts.

The cast compressor wheel in the Gen1 turbocharger is designed with broad vane geometry to ensure consistent airflow at mid-range RPMs. This design choice balances manufacturing cost with reliable performance, though it may result in slightly slower spool times compared to billet designs.

Related Blog: How Does a Pulsar Turbo Compare to a Garrett Turbo for Australian Drivers?

Gen1 turbochargers deliver full boost in 1.2–1.4 seconds at 1 bar, supporting 300–500 hp applications. Efficiency peaks around 70 percent in the mid-flow region, making them suitable for daily-driven tuned vehicles. Their stability across a broad RPM band ensures reliable power delivery without abrupt transient spikes.

Gen1 units excel in serviceability and long-term reliability thanks to their straightforward journal bearing design. With routine oil and filter changes every 10,000 km and bearing inspections at rebuilds, Gen1 turbos often exceed 100,000 km of service before major overhauls are required. Cast wheel repairs are also more cost-effective than billet replacements.

The Gen1 architecture’s proven reliability provides a clear benchmark for the enhancements built into Gen2.

Pulsar Gen2 turbochargers elevate every performance metric by integrating dual ceramic ball bearings and billet compressor wheels within an aerodynamically refined housing. These innovations yield dramatically faster spool, higher efficiency, and extended power potential up to 900 hp.

Key Gen2 improvements include:

Dual Ceramic Ball Bearing SystemCeramic balls operate with minimal friction and heat tolerance far beyond steel, cutting spool time by up to 30 percent and boosting bearing life under high-boost tuning.

Billet Aluminum Compressor WheelPrecision-machined from 7075–T6 aluminum, the billet wheel’s thinner, swept-blade vanes optimize airflow and reduce rotational inertia for sharper throttle response.

Advanced Aerodynamic EnhancementsRedesigned turbine and compressor flow paths minimize turbulence, leveraging CFD-tested volute shapes that improve peak efficiency by 5–8 percent.

Spool Time and Transient ResponseGen2 units reach full boost in as little as 0.8–1.0 seconds at 1 bar, delivering instantaneous throttle feedback and reducing turbo lag.

Enhanced Horsepower and Torque PotentialThe combined bearing and wheel upgrades support up to 900 hp, with high-flow housings and improved cooling offering tuning headroom for aggressive builds.

These advancements establish Gen2 as the go-to solution for enthusiasts demanding maximum power, minimal lag, and proven durability.

Gen2 turbos utilize a dual ceramic ball bearing cartridge, where silicon nitride balls maintain near-zero friction even under extreme temperatures. This bearing system reduces rotational drag, accelerates spool, and extends service intervals compared to oil-dependent journal bearings.

The billet compressor wheel features swept, narrow vanes cut from aerospace-grade aluminum. Its reduced mass and refined vane geometry boost flow efficiency and accelerate spool, translating mechanical improvements into sharper boost onset.

Gen2 housings incorporate CFD-optimized volute shapes, smoother scroll transitions, and refined diffuser angles. These design tweaks minimize vortex formation, increase pressure recovery, and elevate overall compressor maps for broader efficiency islands.

Gen2 turbochargers incorporate advanced aerodynamic enhancements, such as CFD-optimized volute shapes and refined diffuser angles, to minimize turbulence and improve peak efficiency. These design improvements contribute to faster spool times and enhanced overall performance.

Related Blog: What Pulsar Turbo is the Best Upgrade for a Ford Falcon XR6 in Australia?

By combining ceramic bearings and a lighter billet wheel, Gen2 turbos achieve full boost in 0.8–1.0 seconds, shaving up to 30 percent off Gen1 spool time. This improvement yields immediate throttle response and improved transient performance in street and track applications.

Gen2 turbochargers unlock 30–100 hp more than Gen1 variants, depending on model size and tuning. High-flow turbine housings and reinforced bearing cartridges support peak power outputs up to 900 hp, with substantial gains in mid-range torque for streetable builds.

Gen2’s holistic enhancements underscore a new performance benchmark—one that transforms both street and competition vehicles.

Below is a component-level comparison of Pulsar Gen1 and Gen2 turbochargers, highlighting core design differences and performance outcomes.

|

Product |

Feature |

Value (Gen1) |

Value (Gen2) |

|---|---|---|---|

|

Bearing System |

Friction Reduction |

Oil-film journal bearing |

Dual ceramic ball bearing |

|

Bearing System |

Spool Time Impact |

Standard (1.2–1.4 s to full boost) |

Fast (0.8–1.0 s to full boost) |

|

Compressor Wheel Design |

Material |

Cast aluminum |

Billet 7075-T6 aluminum |

|

Compressor Wheel Design |

Inertia & Response |

Heavier inertia, moderate response |

Low inertia, sharp throttle response |

|

Aerodynamics |

Flow Path Optimization |

Standard volute geometry |

CFD-optimized scroll and diffuser angles |

The precision of Gen2’s bearing and wheel upgrades not only improves spool characteristics but also enhances turbocharger efficiency and reliability when compared to Gen1.

|

Product |

Feature |

Value (Gen1) |

Value (Gen2) |

|---|---|---|---|

|

Spool Time |

Time to 1 bar boost |

1.2–1.4 seconds |

0.8–1.0 seconds |

|

Horsepower Potential |

Maximum Safe Output |

Up to 500 hp |

Up to 900 hp |

|

Torque Potential |

Mid-range Torque Gain |

Moderate |

High |

|

Reliability & Service |

Maintenance Interval |

Rebuild every 100,000 km |

Rebuild every 120,000 km |

|

Durability |

Bearing & Wheel Life |

Standard journal bearing lifespan |

Extended ceramic bearing and billet wheel longevity |

Gen2’s combination of advanced ceramics, billet components, and refined aerodynamics delivers a comprehensive performance uplift over Gen1 designs.

Upgrading from Gen1 to Gen2 makes sense when you require faster spool, higher power capacity, and extended service intervals—especially in high-boost or track-focused applications. The cost difference is offset by performance gains in horsepower, throttle response, and bearing life.

Consider upgrading when:

Performance Gains Justify CostA typical Gen2 upgrade yields 30–100 hp more and 30 percent faster spool, balancing upgrade expense against power and lag reduction benefits.

Vehicle Types and Tuning ScenariosHigh-output 4-cylinder engines, drift cars, and forced-induction V6/V8 platforms benefit most from Gen2’s rapid transient response and high-flow capacity.

Cost ConsiderationsGen2 units are priced 20–30 percent higher than Gen1 counterparts. When spread over longer service intervals and increased tune headroom, the value proposition strengthens.

QuickBitz Upgrade SupportQuickBitz offers expert installation and bespoke ECU calibration for Gen2 turbos, ensuring your upgrade delivers promised gains without compromise. Learn about our Technical Information - QuickBitz to prepare for your upgrade.

QuickBitz brings Pulsar Turbo Systems’ Gen1 and Gen2 solutions to Australian performance enthusiasts with tailored support, local stock, and proven tuning expertise.

QuickBitz stocks the full range of Pulsar turbos across both generations, including popular sizes for 4-cylinder compressors and high-flow V6/V8 applications—browse the Pulsar Turbos collection to find your model.

Our in-house calibration specialists deliver bespoke ECU maps, boost control strategies, and dyno validation to unlock each turbo’s full potential. QuickBitz’s installation packages ensure optimal oil feed, cooling, and wastegate setups.

We maintain a comprehensive Technical Information - QuickBitz hub with installation guides, compressor maps, bearing maintenance checklists, and fluid specifications for both Gen1 and Gen2 units.

Every Pulsar turbo sold by QuickBitz undergoes bench testing and on-vehicle dyno validation. Our performance data and reliability analysis deliver peace of mind for street, track, and competition builds.

QuickBitz’s local expertise, product availability, and service excellence complete the Pulsar turbo experience for Australian performance aficionados.

The main difference lies in Gen2’s dual ceramic ball bearing system and billet compressor wheel, which produce up to 30 percent faster spool, improved aerodynamics, and nearly double the horsepower potential compared to Gen1’s journal bearing and cast wheel design.

Yes, Gen2 turbos reach full boost in 0.8–1.0 seconds at 1 bar, compared to 1.2–1.4 seconds for Gen1, thanks to reduced friction and inertia from ceramic bearings and a billet wheel.

Depending on model and tuning, Gen2 units deliver 30–100 hp more than Gen1, with maximum safe outputs up to 900 hp versus Gen1’s 500 hp threshold.

Both generations are built for durability, but Gen2’s ceramic bearing cartridge and billet wheel extend service intervals to 120,000 km, reducing rebuild frequency compared to Gen1’s 100,000 km schedule.

Ceramic ball bearings reduce friction, tolerate higher temperatures, accelerate spool by up to 30 percent, and deliver longer bearing life under high-boost conditions, enhancing both performance and reliability.

These clarifications address the most common concerns, feeding directly into installation and tuning best practices.

Proper installation and tuning maximize each generation’s strengths and extend service life.

Oil Feed and Drain Lines must be upsized to maintain adequate lubrication under boost.

Gaskets and Flanges should be inspected for warp and replaced to prevent boost leaks.

Wastegate Actuation must be calibrated to match the journal bearing’s spool characteristics.

Bearing Cartridge Fitment requires precise shaft alignment to protect ceramic balls.

Coolant Cooling Options may be added to manage higher operating temperatures.

Boost Control Calibration must compensate for 30 percent faster spool to avoid overboost.

Optimize boost ramp rates to harness rapid spool without AFR spikes.

Use closed-loop boost control with high-speed MAP sensors for consistent pressure.

Implement staged fueling maps to match peak airflow and maintain safe EGTs.

Perform oil and filter changes every 8,000–10,000 km using high-zinc synthetic oils.

Inspect bearing play and seals at each major service interval.

Rebuild turbos with genuine Pulsar parts—journal kits for Gen1, ceramic cartridges for Gen2.

Pulsar Gen1 and Gen2 turbos each offer distinct advantages, and following proper installation and tuning practices maximizes their respective strengths.

Gen2’s advanced bearing and wheel technologies deliver a notable leap in turbocharger performance, yet a Gen1 setup still provides reliable power for moderately tuned engines. QuickBitz’s expert guidance and technical resources ensure your choice aligns with driving goals and budget constraints.

Ready to transform your forced induction setup? Explore the complete Pulsar turbo range and professional tuning solutions at QuickBitz today.