Common Types of A...

Dec 03, 2025

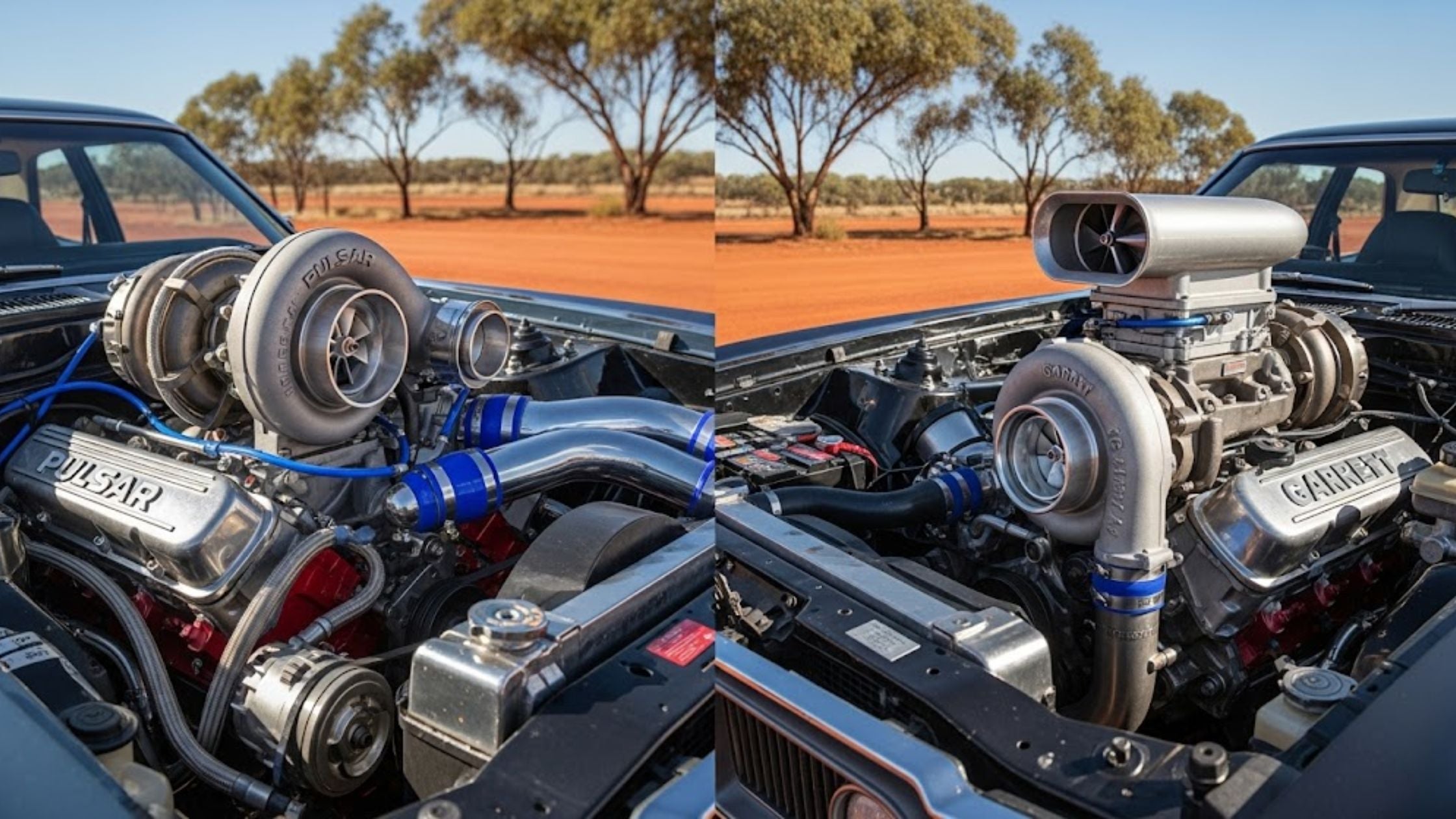

Choosing the right turbocharger can revolutionize your vehicle’s power and reliability across Australia’s diverse driving landscapes. In this article, we dive into the Pulsar vs Garrett debate, exploring six key areas—performance, reliability, cost-effectiveness, model suitability, installation, and real-world case studies—to help Aussie enthusiasts and professional tuners get the most bang for their buck. QuickBitz is here to provide expert insights and a top-notch selection of performance parts and tuning services, guiding you from comparison to installation.

The performance gap between Pulsar and Garrett turbos boils down to core design choices that influence boost response, airflow efficiency, and power delivery, helping enthusiasts find a solution that matches their driving style. Understanding how each brand manages spool time, peak output, and thermal management is crucial in an Australian turbocharger comparison.

Turbocharger technology has come a long way, with modern designs zeroing in on efficiency and reduced lag. Innovations like ball bearings and optimized aerodynamics boost response and overall engine performance.

Read more, Are Pulsar Turbos a Good Option for Performance Builds in Australia?

Pulsar turbos are known for their rapid spool, thanks to ball-bearing cores that cut down on turbo lag and speed up boost onset, enhancing throttle response for both street and circuit use. Their compressor housings feature optimized inducer geometries that speed up airflow and support consistent mid-range torque. Users report snappy boost engagement from 1,800 to 6,500 rpm, making Pulsar a compelling performance-per-dollar choice. This quick-spool trait highlights Pulsar’s value-driven performance focus, leading into Garrett’s advanced efficiency features.

Garrett turbos shine with high efficiency through precision aerodynamics and ceramic ball bearings that cut friction, resulting in sustained boost and better fuel economy. Their variable geometry technology and advanced compressor maps optimize airflow across a wide rpm range, enhancing peak power and part-throttle drivability. These innovations deliver smooth power ramps and lower exhaust back-pressure while supporting high-boost applications. Such efficiency gains underscore Garrett’s premium engineering heritage, setting the stage for a direct horsepower comparison across popular models.

Here’s a side-by-side spec table highlighting peak output for common Pulsar and Garrett turbos on Aussie builds.

|

Entity |

Peak Horsepower (hp) |

Peak Torque (Nm) |

|---|---|---|

|

Pulsar G25-660 |

660 |

740 |

|

Pulsar G30-770 |

770 |

820 |

|

Garrett G25-660 |

660 |

760 |

|

Garrett G30-770 |

770 |

830 |

Here are three primary heat-management approaches used by Pulsar and Garrett turbos in Australian conditions:

Pulsar’s water-cooled bearing housing keeps oil temperatures stable under sustained load.

Garrett’s integrated dual-pass water jacket enhances thermal dissipation for heavy-duty racing.

Both brands offer optional external oil coolers and high-capacity intercooler kits for extreme temperatures.

These solutions ensure consistent boost and protect bearings during prolonged spirited driving, paving the way to assess long-term reliability under Australian conditions.

Reliability and durability reflect a turbocharger’s build quality, materials, and support network, which are critical for Australia’s hot climates and long highway runs. Evaluating common issues, brand reputation, and warranty offerings helps drivers choose a turbo that stands up to daily use and high-performance demands.

The reliability of a turbocharger is crucial, especially in demanding conditions. Factors such as build quality, materials, and the support network influence a turbocharger's longevity. Regular maintenance and professional installation are essential for ensuring optimal performance and minimizing potential issues.

Owners have noted these occasional service concerns with Pulsar units:

Slight shaft play developing after 20,000 km under heavy track use.

Oil leakage from aftermarket flanges when improperly sealed.

Compressor wheel damage from debris in harsh off-road environments.

Garrett turbos are renowned for robust journal-bearing and ceramic bearing designs that endure extended high-boost cycles. Their global R&D and OEM heritage contribute to stringent quality control, resulting in consistent long-term performance. This legacy underpins Garrett’s reputation for durability and makes their units a benchmark for reliability.

Australian drivers benefit from local support and warranties as follows:

Pulsar turbos carry a two-year warranty through authorized resellers, with replacement programs for manufacturing defects.

Garrett units are backed by a three-year international warranty when registered via authorized distributors.

QuickBitz offers extended technical support and tuning advice via its Technical Information to optimize warranty compliance.

Cost-effectiveness measures the balance between purchase price, installation/tuning expenses, and performance gains—essential for calculating true performance per dollar in a turbocharger comparison Australia.

When selecting a turbocharger, cost-effectiveness is a key consideration, balancing purchase price, installation costs, and performance gains. The total cost of ownership, including tuning and maintenance, should be evaluated to determine the true value of a turbocharger.

The following table outlines typical retail pricing and a simple performance-per-dollar metric.

|

Entity |

Price Range (AUD) |

Performance per Dollar (hp/AUD) |

|---|---|---|

|

Pulsar G25-660 |

1,200–1,400 |

0.55 |

|

Pulsar G30-770 |

1,400–1,600 |

0.54 |

|

Garrett G25-660 |

1,500–1,700 |

0.44 |

|

Garrett G30-770 |

1,700–1,900 |

0.40 |

Key components of total cost include:

Professional installation fees, average 300–500 AUD.

Custom ECU tuning sessions, 500–800 AUD depending on engine complexity.

Ancillary parts (exhaust flanges, oil lines, intercoolers), 200–600 AUD.

Scheduled servicing every 20,000 km, 150–250 AUD per service.

Accounting for these factors shows how initial savings translate into long-term value, guiding drivers toward the next question of performance builds versus daily driving.

For daily use, Pulsar’s quick spool and affordability deliver strong mid-range torque suited to street conditions. For high-power builds, Garrett’s superior thermal management and advanced aerodynamics justify its premium price by providing stable high-rpm performance.

Choosing the right turbo model depends on engine platform, power goals, and driving environment. Matching model characteristics to common Australian engines ensures optimal performance and reliability.

Nissan SR20DET: G25-660 for balanced spool and torque.

Ford Barra: G30-770 for high-boost muscle car builds.

Toyota 2JZ: G35-900 for extreme power applications.

These pairings illustrate Pulsar’s adaptability across popular local platforms and lead into Garrett’s preferred models.

G25-660 on Mazda 6 MPS for a street/track balance.

G30-770 on Holden Commodore V8 conversions.

G35-900 on high-compression turbo drift cars.

These choices reflect Garrett’s reputation for precision and set up the discussion on vehicle application factors.

Vehicle use—daily commuting, towing, circuit racing—dictates turbo characteristics: quick spool for street cars, robust heat management for towing, and high flow for track use. Balancing these factors with engine size and intended power output ensures the correct Pulsar or Garrett model selection for each application.

Proper installation and calibration unlock a turbo’s full potential while safeguarding reliability. Australian drivers benefit from understanding brand-specific fitment requirements and leveraging local tuning expertise.

Flange compatibility – match T3, T4 or hybrid flanges to exhaust manifolds.

Oil and water feed ports – verify thread sizes (M8 vs 1/8 NPT) prior to plumbing.

Compressor housing orientation – ensure proper intercooler piping alignment.

Attention to these details prevents leaks and maximizes boost control, opening the way to discuss tuning impacts.

Experienced Australian tuners adapt ECU maps to local fuel quality, ambient temperatures, and driving styles. Their precision in adjusting boost targets, fuel trims, and ignition timing ensures turbos operate within safe limits while delivering peak efficiency.

Optimizing turbo gains requires:

E85 flex-fuel tuning to leverage higher octane and cooler charge temperatures.

98 RON pump tuning for balanced street drivability.

Staged boost increase strategies to validate hardware before full power calibration.

These approaches deliver reliable performance under Australia’s varied fuel and climate conditions, preparing for real-world validation through case studies.

Case studies demonstrate how theoretical advantages translate into measurable on-track and street results. Reviewing these builds provides insight into expected outcomes and informs selection decisions.

In the “Project Barra Boost” Ford Falcon XR6 build, the Pulsar G35-900 achieved:

|

Entity |

Feature |

Measured Value |

|---|---|---|

|

Pulsar G35-900 |

Peak Power |

500 hp @ 6,200 rpm |

|

|

0–100 km/h |

4.9 seconds |

|

|

Thermal Stability |

15% drop after 10 laps |

This data confirms Pulsar’s capacity for sustained power on large six-cylinder engines and transitions into comparing Garrett’s track performance.

Consistent 410 hp at 6,000 rpm under endurance conditions.

Less than 5 °C increase in charge-air temperature over 30 minutes.

Improved lap times by 1.2 seconds compared to the previous journal-bearing unit.

These findings highlight Garrett’s thermal advantages in racing environments and lead into driver feedback on long-term use.

Stable boost curves over 50,000 km with scheduled oil change intervals.

Minimal shaft play in Garrett units after extended track use.

Occasional bearing noise in non-water-cooled Pulsar Turbo Australia setups if oil cooling is insufficient.

This real-world insight reinforces the importance of matching turbo choice to usage patterns and finalizes the decision-making guide.

Selecting between Pulsar and Garrett turbos requires weighing performance goals, budget, and vehicle use. A structured decision framework simplifies this process.

Target horsepower and torque requirements.

Desired spool characteristics and throttle response.

Budget constraints and performance-per-dollar priorities.

Engine platform compatibility and space limitations.

Clarifying these factors ensures a focused comparison and flows into the role of driving conditions.

Daily urban use favors quick spool and broad powerbands.

Towing demands robust cooling and sustained boost.

Track applications require high flow capacity and thermal stability.

Aligning turbo specs with real-world conditions ensures reliability and peak performance.

Upgrading to the right turbocharger—whether Pulsar’s value-driven spooling performance or Garrett’s advanced efficiency and durability—depends on matching your driving goals to each brand’s strengths. Both offer substantial gains for Australian vehicles when paired with proper installation and tuning. By analyzing your power targets, reliability requirements, and budget, you can select the turbo that maximizes performance per dollar and enjoyment behind the wheel. Partner with QuickBitz for expert advice, quality parts, and professional tuning services to complete your upgrade with confidence.

Dec 03, 2025

Dec 03, 2025

Dec 03, 2025