Common Types of A...

Dec 03, 2025

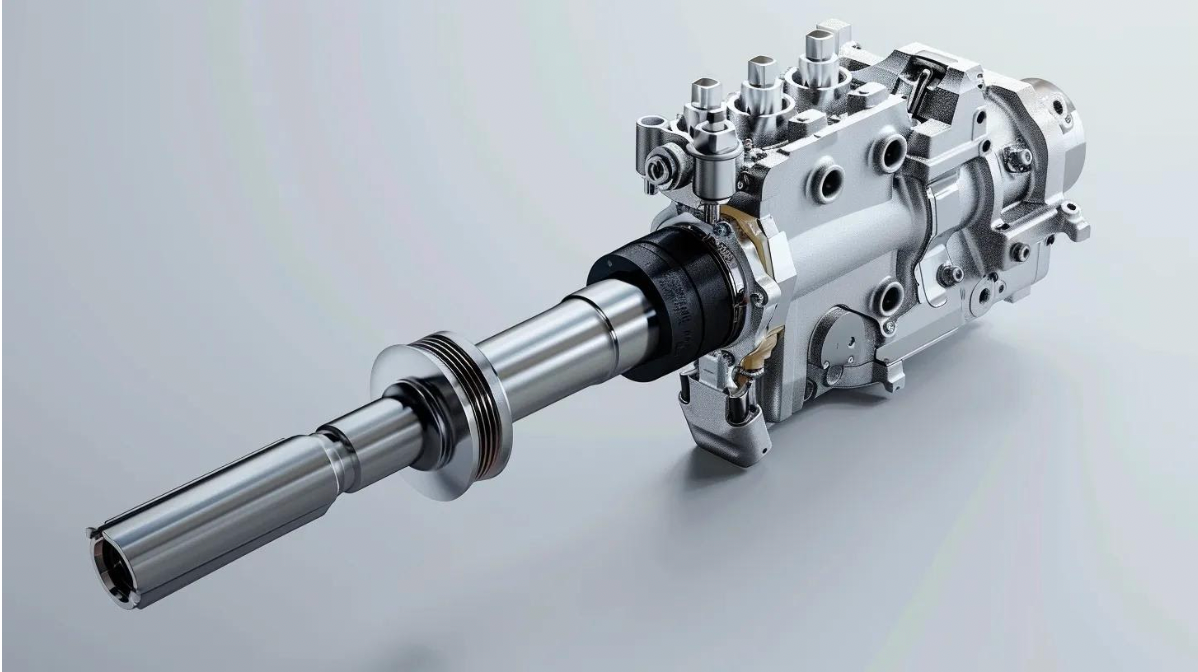

Bosch Fuel Injectors are widely respected for their engineering pedigree, precision manufacturing, and broad OEM coverage, and that reputation shapes how mechanics, tuners and vehicle owners choose replacements or upgrades. In everyday driving, what matters most is reliable atomisation, consistent flow rates and long-term durability, and Bosch injectors deliver predictable performance across passenger cars, light commercial vehicles and many diesel applications. This post walks through a detailed on-page comparison of Bosch Fuel Injectors against other leading brands such as Denso and Delphi, explains technical differences, and gives practical buying and maintenance guidance so you can make a confident decision.

Bosch Fuel Injectors are often recognised for their extensive OEM usage and a wide range of part numbers that match many European and global marques. Bosch specialises in both petrol and diesel injectors with a strong presence in common rail diesel systems and port injection petrol systems, and their engineering emphasis is on tight tolerances and consistent spray patterns.

Denso injectors bring a reputation for compact design and excellent electrical reliability, often favoured in Japanese vehicles and many Asian-built platforms. Denso focuses on high-precision components that integrate tightly with OEM engine control strategies, which can make them particularly effective where ECU mapping and pulse-width modulation characteristics are optimised around Denso hardware.

Delphi has a strong heritage in diesel systems and offers solid common rail injectors and unit injector technologies. Delphi components tend to perform well in systems where fuel pressure dynamics and mechanical robustness are prioritised. Delphi injectors are commonly seen in a range of European and some American vehicles and are respected for their serviceability and aftermarket reconditioning options.

Bosch Fuel Injectors use multiple design elements to achieve atomisation, flow control and electrical stability. In petrol engines, Bosch offers multi-hole nozzles and carefully shaped spray cones that improve mixture formation in modern direct and port-injected engines. In diesel systems, Bosch pioneered high-pressure common rail injection stacks and has long been a leader in piezo and solenoid valve control strategies that enable ultra-fine fuel delivery at very high pressure.

Bosch’s quality control across machining, assembly and testing ensures many injectors leave the factory with matched flow characteristics, which is important for cylinder-to-cylinder balance and emissions compliance. Where vehicles require ECU coding or injector adaptation, Bosch often supplies the necessary calibration data or part cross-references that workshops need.

Denso injectors prioritise compactness and electrical durability, frequently using high-quality solenoid coils and precisely machined needle seats. Their spray patterns are optimised for the combustion chambers used by Japanese and Korean manufacturers, making them an excellent fit where the engine management systems anticipate that hardware behaviour. For turbocharged petrol engines and many diesel applications, Denso injectors provide stable electrical response and predictable flow decay characteristics as the injector ages. Learn more about the benefits of genuine Bosch fuel injectors and why choosing the right injector brand matters.

Denso’s approach to materials and coil design tends to limit electrical failures and helps maintain consistent opening times and response to duty cycles, which is particularly useful in stop-start traffic and city driving where short, frequent injection events dominate.

Delphi’s injector portfolio is notable for diesel systems and includes a variety of common rail solutions tailored to higher-pressure environments and heavy-duty use. Delphi designs often emphasise mechanical strength and ease of reconditioning, with parts and service networks that support rebuilds. This can be cost-effective for fleet operators who plan long service lives and periodic overhaul.

Delphi injectors typically exhibit rugged internal sealing and valve construction, making them less sensitive to certain contaminants compared with some competitors, though all injectors require clean fuel and correct filtration to avoid premature wear.

When comparing atomisation and spray pattern, Bosch often achieves very fine, evenly distributed droplets that support more complete combustion and lower particulate generation in diesel applications. Denso matches closely in petrol applications, where precise atomisation improves throttle response and idle stability. Delphi’s spray patterns are engineered for reliability under heavy load and may prioritise penetration and mixing in high-pressure diesel systems.

Flow rate accuracy is critical. Bosch maintains tight manufacturing tolerances so that matched injector sets keep cylinder-to-cylinder variance low, which preserves smoothness and helps the ECU balance trims. Denso offers similarly tight control, particularly for factory-specified replacements. Delphi’s flow consistency is robust and suited for higher-pressure scenarios, but matching flow specifications when swapping brands requires careful cross-referencing.

Electrical response and solenoid behaviour matter for tuning and ECU compatibility. Denso’s electrical characteristics are often favoured where ECU mapping expects particular opening times and coil current profiles. Bosch injectors offer excellent compatibility with many ECUs but sometimes require coding in modern vehicles. Delphi designs are straightforward electrically and tend to be easy to integrate in diesel control systems.

All modern injectors can fail from contamination, corrosion, thermal stress or electrical wear. Bosch injectors are prone to failures typical for any high-precision injector: build-up from poor fuel quality, seal degradation and occasional electrical coil breakdowns. Denso injectors are generally robust electrically but can be sensitive to varnish and carbon deposits in petrol systems if fuel quality and servicing intervals are neglected. Delphi injectors, especially diesel variants, can show wear from particulates and water contamination but are often engineered to be reconditioned successfully.

Service history, fuel filtration, and regular maintenance are far more decisive for longevity than brand alone. Reusing old seals, fitting incompatible rails or neglecting recommended fuel filter changes will shorten injector life regardless of brand.

Original equipment (OE) injectors from Bosch, Denso or Delphi are made to factory specs and come with manufacturer guarantees and match-fit reliability. OE parts are the safest option for owners who prioritise warranty compliance and exact fitment. Aftermarket injectors can offer cost savings and sometimes performance improvements, but quality varies widely between manufacturers and remanufacturers.

When considering OE versus aftermarket, check for flow certification, bench testing data, warranty period and return policy. Remanufactured Bosch injectors that are flow-tested and rebuilt with OEM-grade components can be a cost-effective alternative. Beware of no-name injectors that do not provide matched flow reports or have unclear electrical characteristics; these can complicate ECU trims and driveability.

Injector compatibility is more than a physical connector match. Engine management systems expect specific injector response curves, flow rates and input impedance. Mismatched injectors can result in uneven idle, incorrect air–fuel ratios and diagnostic fault codes. Many modern vehicles require injector coding, adaptation or reprogramming after replacement, particularly when changing brand or part number.

Always confirm connector type, resistance (high-impedance vs low-impedance), and required calibration steps. If the replacement differs from OEM spec, plan for ECU tuning or injector offset adjustments to maintain drivability and emissions compliance.

Price differences between Bosch, Denso and Delphi often reflect market positioning, availability and OEM relationships. Bosch can be slightly more expensive in regions where they dominate OEM supply, while Denso often sits competitively for Japanese vehicle replacements. Delphi’s diesel focus means its pricing is influenced by heavy-duty and fleet markets.

Reconditioning injectors can lower initial replacement cost, but factor in the quality of the rebuild. A professionally reconditioned Bosch or Delphi injector with a flow report and pressures verified on a calibrated bench can provide near-OE performance. For performance upgrades, aftermarket injectors or higher-flow Bosch/Denso units might carry higher upfront cost but deliver predictable gains when correctly matched and tuned.

Regular fuel filter changes and ensuring good fuel quality are the simplest, most effective steps to protect injectors. Use manufacturer-recommended service intervals and consider fuel system cleaners sparingly and only from reputable suppliers. When working on fuel systems, avoid running the tank too low as that increases the risk of drawing contaminants into the pump and rail.

When replacing injectors, replace seals, use new o-rings and fit anti-seize where recommended. If cleaning injectors, use professional bench ultrasonic cleaning and flow testing rather than aggressive on-vehicle cleaning methods that risk damage.

Buy from reputable distributors or OEM channels to avoid counterfeit units. Genuine Bosch, Denso and Delphi parts carry clear branding, part numbers and packaging quality that counterfeit suppliers often fail to replicate. Request flow test certificates for rebuilt injectors and ask for bench test results where possible.

or specific part matching, use OEM part numbers or a trusted cross-reference tool. When in doubt, consulting dealership parts departments or authorised distributors ensures correct fitment and warranty coverage.

Start by identifying the exact OEM part number, fuel system type (port vs direct injection, common rail vs unit injector), and recommended flow rates. Confirm electrical impedance and connector style. Decide whether you want OE replacements for guaranteed fit and calibration or a remanufactured alternative with a flow certificate.

If you plan tuning or power upgrades, select injectors rated for the desired fuel flow and ensure your ECU will accept the new injector profile or can be tuned accordingly. Fleet operators should weigh rebuildability and lifecycle costs, while everyday owners should prioritise brand-matched replacements for warranty and reliability.

|

Attribute |

Bosch |

Denso |

Delphi |

|---|---|---|---|

|

Typical OEM presence |

High across European brands; broad global coverage |

High with Japanese and Asian manufacturers |

Strong in European diesel and some American applications |

|

Design emphasis |

Precision atomisation; common rail leadership |

Compact electrical reliability; tight solenoid control |

Robust mechanical design; reconditioning-friendly |

|

Best for |

Mixed petrol and diesel OEM replacements |

Petrol engines and Japanese fitments |

Diesel-heavy applications and fleets |

|

Common failure causes |

Contamination, seals, electrical wear |

Varnish/carbon deposits, electrical ageing |

Particulate wear, contamination; rebuildable |

|

Ease of reconditioning |

Good, many remanufacturers support |

Supported but parts vary |

Excellent, widely reconditioned |

Sources: Manufacturer technical specs and industry bench testing reports.

On everyday passenger cars such as small European hatchbacks or mid-size sedans, Bosch Fuel Injectors often match the factory specification and maintain smooth idling and emissions compliance without ECU reprogramming. For Japanese cars, Denso is frequently the easiest swap because the injectors align with factory ECU timing and electrical profiles. For diesel commercial vans and trucks, Delphi injectors provide the robust service intervals and reconditioning pathways fleet operators value.

In performance builds, enthusiasts may choose higher-flow injectors from Bosch or specialised aftermarket brands, but proper ECU remapping and fuel system upgrades (pump, rail pressure) are essential. Changing to a different brand can introduce unexpected driveability quirks unless the new part is properly calibrated.

Injector precision directly affects fuel atomisation and air–fuel mixing efficiency. Better atomisation reduces incomplete combustion and particulate formation in diesel engines while improving throttle response and economy in petrol engines. Bosch Fuel Injectors often deliver good emissions performance thanks to tight spray control; Denso also supports low-emission operation when paired with matching ECU profiles. Delphi’s high-pressure diesel designs help reduce soot when properly calibrated.

Poorly matched or ageing injectors can increase tailpipe emissions, reduce fuel economy and create combustion instability that triggers emission-related fault codes.

Installers should always follow torque specs for rails and use new seals and o-rings. Avoid force-fitting connectors and ensure rails are free of debris before reassembly. After fitting, run adaptation procedures if required by the vehicle. If faults appear after replacement, re-check injector wiring, resistance and bench flow values.

Workshops servicing modern vehicles should have access to calibration procedures and injector programming tools, particularly for models that require coding after part replacement.

Myth: All injectors of the same flow rate are interchangeable. Fact: Flow rate is only one parameter; spray pattern, response time and impedance matter for ECU behaviour. Myth: Cheaper aftermarket injectors always save money. Fact: Poor fitment or mismatched electrical characteristics can cost more in tuning and repairs. Myth: Cleaning an injector on-car always restores performance. Fact: Bench testing and ultrasonic cleaning are the only reliable ways to restore and confirm flow and spray pattern.

Injector technology is evolving alongside tighter emissions standards and alternative fuels. Piezoelectric control, finer multiple-hole nozzles and higher pressure common rail systems continue to improve combustion efficiency. Electrification trends and hybridisation shift some focus away from traditional injectors in certain vehicle segments, but for pure internal combustion engines, injector precision remains a critical performance and emissions control lever.

Injector materials and coatings must withstand different chemistries. Diesel injectors encounter higher pressures and different lubricity needs, while petrol injectors must tolerate additives and evaporative conditions. Alternative fuels like biodiesel, ethanol blends and synthetic fuels require compatibility checks because solvent effects and contaminated supplies can accelerate wear.

Common signs of failing injectors include rough idle, misfire codes, fuel odour, poor acceleration and inconsistent fuel trims. On-vehicle diagnostics include monitoring short- and long-term fuel trims, cylinder balance tests and resistance checks. Bench testing with calibrated flow benches and spray pattern inspection provides definitive assessment and should be requested when buying remanufactured units.

Buy from authorised distributors, OEM parts departments, or reputable remanufacturers who provide flow reports and warranties. Ask for part numbers, flow test certificates, and whether the injector is new, OE or remanufactured. For remanufactured units, insist on documented bench testing and new seals.

In mid-replacement research I often point customers to Bosch Fuel Injectors as a baseline because their OE presence makes cross-referencing straightforward and the engineering data easier to obtain for workshops fitting replacements.

A practical tip when searching stock lists is to filter by OEM part number and vehicle model to avoid selecting physically compatible but electrically or flow-incompatible units. If you’re exploring wider options, browse the store’s organised categories and compare specifications on the manufacturer product pages and the Shop by Brand listings to ensure you’re comparing like-for-like.

If technical details are important to your decision, make sure the supplier supplies bench-tested specifications and part-specific calibration notes; check the product pages and technical datasheets available under Technical Information to confirm flow rates, impedance and recommended coding steps.

Reconditioning makes sense where the rebuild uses OEM-grade components and includes flow matching. Fleet operators and classic car owners often favour reconditioning to preserve authenticity and manage costs. New OE units are preferable for recent vehicles still under warranty or where longevity without prior wear is a priority.

Avoid reusing old seals, neglecting rail or injector bore cleaning, and ignoring ECU coding requirements. Ensure you replace fuel filters before fitting new injectors to prevent immediate contamination. Use the correct torque settings and never force electrical connectors.

Bosch Fuel Injectors compare favourably to Denso and Delphi across many criteria: precision atomisation, wide OEM support and consistent flow characteristics make Bosch a strong choice for many petrol and diesel vehicles. Denso excels where compact electrical reliability and Japanese fitment compatibility are priorities, while Delphi stands out in diesel robustness and rebuildability for fleet and heavy-duty applications. Ultimately, the best choice depends on the vehicle’s original specification, intended use, and whether you prioritise OE fidelity, cost or reconditioning pathways. For reliable sourcing, professional bench testing and fitment services, Quickbitz offers hands-on support and can help match the right injector solution to your vehicle and budget.

Bosch injectors offer excellent flow matching and spray control; for many performance builds they perform very well, but the best choice depends on the target flow rate, ECU compatibility and the vehicle’s original injector characteristics.

Some modern vehicles require injector coding or adaptation after replacement; whether Bosch injectors need coding depends on the vehicle make and ECU, so check the service procedures for your model.

Yes, provided the remanufacturer supplies flow-tested, bench-certified units that match required specifications; careful cross-referencing and validation are essential.

There is no single interval; many injectors last well beyond 150,000 km with good fuel quality and maintenance. Replace sooner if you observe misfires, poor trims or if bench testing shows out-of-spec flow or spray patterns.

Signs include rough idle, misfires, loss of power, increased fuel consumption, fuel odour and inconsistent cylinder balance. Diagnostics and bench testing confirm the diagnosis.