Common Types of A...

Dec 03, 2025

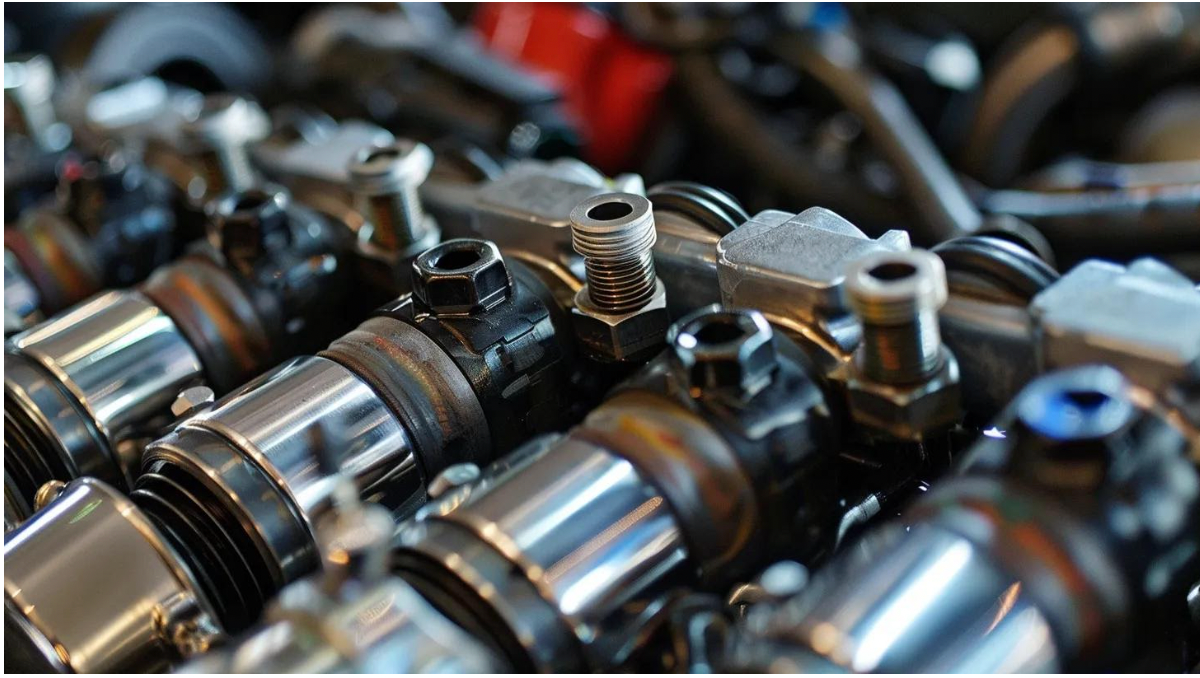

Bosch Fuel Injectors are at the heart of modern petrol engines that rely on gasoline direct injection, a technology that changed how fuel is delivered, how engines breathe, and how drivers experience performance and economy. In this article I explain what gasoline direct injection (GDI) is, why it matters, how Bosch’s GDI injectors work and what makes them important to vehicle owners, mechanics and fleet managers across Australia. You’ll get clear, on‑page guidance about symptoms of injector problems, maintenance, replacement choices and how to choose the right replacement injector for your vehicle.

Direct injection technology moved from niche racing use into mainstream production because it gives manufacturers a clearer path to higher efficiency, lower CO2 emissions and better power density without changing engine displacement. Instead of spraying fuel into the intake port, GDI injectors deliver pressurised petrol directly into the combustion chamber. That tighter timing and placement of fuel enables leaner mixtures during cruise, higher compression ratios, and sharper throttle response. The result is better fuel economy in real‑world driving, improved low‑end torque and the opportunity to meet increasingly strict emissions regulations.

Direct injection influences three combustion variables: the air–fuel mixing pattern, the timing of injection events and the quality of atomisation. Injecting into the cylinder allows staged injection events — for example, a small pilot injection to improve ignition stability followed by a main injection for power — which reduces knock and enables more aggressive ignition timing. Better atomisation reduces local fuel-rich pockets that create soot in some engines but, conversely, can increase particulate formation if injection timing and EGR are not managed correctly.

Bosch Fuel Injectors are engineered for precision, repeatability and long life. Bosch’s portfolio includes solenoid and piezo injectors for direct injection applications, with designs optimised for spray pattern, sealing, and thermal durability. The injectors are controlled by the engine control unit (ECU), which times the injector opening in microseconds based on inputs from sensors such as crank and cam position, manifold pressure, intake air temperature and oxygen sensors.

Bosch’s advantage lies in manufacturing tolerance, nozzle geometry and robust electronics. Their injector regimes support multiple injection events per cycle and ultra‑fast switching, which is essential for modern stratified‑charge and homogeneous charge strategies. For petrol direct injection that means improved power delivery and throttle response while reducing fuel consumption under steady cruise.

There are two mainstream types of injectors used in GDI engines: solenoid actuated injectors and piezoelectric injectors. Solenoid injectors are durable and cost‑effective and are used in many mass‑market engines. Piezo injectors switch faster and with finer control over the injection profile, which is why they appear in high‑performance engines and premium vehicles where extremely precise fuel metering is required.

Solenoid injectors open when current energises a magnetic coil that lifts a pintle; piezo injectors use ceramic materials that change shape under voltage, moving the needle with sub‑millisecond precision. Both types need high fuel pressures — commonly 100–200 bar in modern GDI systems — and both must maintain tight seals at the injector tip and robust electrical connections inside the engine bay environment.

Bosch injectors are important because they combine engineering tolerances, material science and manufacturing scale to produce an injector that resists clogging, carbon build‑up and electrical failure. Carbon accumulation on the injector tip and intake valves is a known issue with direct injection engines because fuel does not wash past the intake valves as it does in port injection systems. Bosch works on nozzle designs and spray patterns that reduce the formation of locally rich pockets that encourage carbon formation.

Equally critical is the injector’s ability to repeat injection timing reliably over tens of thousands of kilometres. When an injector’s opening time drifts or when spray pattern degrades, you see rough idle, misfires, increased fuel consumption, poor cold starts and elevated emissions. Bosch’s quality control and global R&D mean many replacement injectors are engineered to match or exceed OEM specifications, which keeps drivability consistent and emissions systems functioning as intended.

A failing injector rarely fails silently. You are likely to notice drivability symptoms such as inconsistent idle, stumbling on acceleration, poor throttle response, increased fuel use and hard starting. The engine management light will often illuminate when the ECU detects a lean or rich condition, misfire or deviation from expected injector performance.

Diagnosis should start with a careful visual and electrical inspection: check connector pins for corrosion, measure injector resistance with a multimeter and compare against manufacturer specifications, and use a diagnostic scan tool to read live fuel trim data. Fuel trim drift, especially under steady conditions, is a strong clue to injector or fuel supply irregularities. A fuel balance test — where the current draw or fuel flow of each injector is compared under bench or on‑car testing — helps identify weak or leaking injectors.

In many workshops the practical next step is a spray pattern and flow test on a specialised bench. This confirms whether the injector atomises fuel correctly and returns within acceptable flow tolerances. If carbon or varnish is suspected, ultrasonic cleaning can recover some injectors, but heavily compromised injectors or those with electrical faults should be replaced.

Good maintenance starts with fuel quality and periodic servicing. Use reputable petrol suppliers and follow your vehicle maker’s recommended fuel service intervals. Fuel additives are sometimes suggested to help clean injectors, but they are not a cure for heavy carbon. Where possible, avoid extended idling and short trips that do not allow the engine to reach optimal operating temperature, as these conditions can encourage deposit formation.

When cleaning is needed, professional workshops use ultrasonic cleaning and flow testing to restore spray pattern. Mechanical carbon removal or walnut shell blasting is used on the intake side for severe valve deposits, but this does not clean the injector tip. Replacement injectors, especially Bosch replacements, are a sound choice when cleaning cannot restore performance.

When replacing injectors select a part that matches the original specifications: flow rate, spray pattern, connector and sealing geometry. OEM‑equivalent Bosch injectors are often the safest choice because they match vehicle calibration and durability requirements. Cheap generic injectors may fit physically but can have different spray patterns or flow rates that throw off ECU fuel trims and catalytic converter performance.

Consider whether your vehicle uses solenoid or piezo injectors, and ensure you choose injectors rated for your engine’s maximum rail pressure. If your vehicle uses high‑pressure common rail petrol systems or advanced stratified operating modes, follow the manufacturer’s recommendation for parts and recalibration. After replacement, a professional calibration or injector coding step may be required to ensure the ECU recognises the new injectors and applies correct fuel maps.

Correct installation prevents leaks, electrical faults and early failure. Always replace seals and O‑rings with OEM‑spec parts to avoid fuel leaks or vacuum leaks that upset engine management. Lubricate O‑rings with clean engine oil or recommended assembly lube to prevent tearing during installation. Torque injector hold‑down bolts to the vehicle maker’s specification and confirm rail and injector rail bolt torques.

After installation, check for leaks at the high‑pressure fuel rail connection while the system is pressurised. Reset the ECU fuel trims if required, and perform a road test with live data logging to confirm stable fuel trims and smooth idle. Replace fuel filters if they are overdue; clogged filters increase pump strain and may contribute to poor injection performance.

Bosch injectors are built to last typical service intervals of 150,000 to 300,000 kilometres in normal conditions, but life depends on fuel quality, driving patterns and maintenance. When problems occur, bench testing and targeted cleaning can be cost‑effective. Replacement cost varies by engine and vehicle — high‑pressure piezo injectors and injectors for turbocharged GDI engines tend to be more expensive than conventional solenoid injectors.

When budgeting, account for parts, labour for removal and reinstallation, any intake valve cleaning needed and possible ECU coding. Although a set replacement can seem costly, a correctly matched set of Bosch injectors often pays back through improved fuel economy and avoidance of downstream damage to catalytic converters or particulate filters.

Direct injection petrol engines can produce fine particulates similar to diesel engines when injection events create locally stoichiometric or rich pockets that generate soot. To combat this, manufacturers increasingly fit gasoline particulate filters (GPFs) and tune injection strategies to reduce particulate output. Bosch works with OEMs on injector and ECU strategies that lower particulate formation without sacrificing performance.

As emissions standards tighten, using injectors that meet OEM specifications becomes critical. Poorly performing injectors can push a vehicle over emissions limits, causing failed inspections and increased environmental impact. When replacing injectors, choose units that preserve the original emission control strategy.

|

Injector type |

Typical application |

Key benefit |

|---|---|---|

|

Solenoid GDI injectors |

Mass‑market GDI petrol engines |

Cost‑effective, robust |

|

Piezo GDI injectors |

High‑performance and premium engines |

Extremely fast switching and precision |

|

Port fuel injectors |

Older petrol engines with intake‑port delivery |

Simpler, less particulate risk |

|

Combined systems (port + direct) |

Engines aiming to reduce intake valve carbon |

Best of both for cleanliness and efficiency |

On urban commutes with frequent stop/start, a well‑calibrated Bosch injector set keeps idle stable and avoids the roughness associated with partial injector failure. In highway cruising the precise metering lowers fuel consumption and ensures relaxed fuel trims. For performance driving, injectors that support multiple quick injections improve throttle response and reduce the chance of knock during aggressive tuning.

For fleet operators, consistent injector performance across vehicles keeps maintenance predictable and reduces downtime. For DIY mechanics, sourcing Bosch replacement injectors from a trusted supplier and following installation best practices avoids expensive follow‑up repairs.

One myth is that direct injection inherently causes severe carbon build‑up. While GDI creates conditions where carbon can accumulate on intake valves, design choices such as using port injection as a backup, valve coating, PCV system optimisation, and maintenance practices greatly influence outcomes. Another myth is that all injectors are interchangeable; in reality, nozzle geometry and flow rate differences can cause drivability and emissions issues if mismatched.

A practical myth among vehicle owners is that injector cleaning is always sufficient. In many cases, cleaning helps but does not restore injectors with internal electrical faults or worn pintle seats. Understanding these nuances helps owners choose whether to clean or replace.

Genuine Bosch injectors have precise machining, consistent finish, identifiable part numbers and packaging that protects them from contamination. Purchase from authorised dealers or reputable suppliers and check part numbers against your vehicle’s VIN cross‑reference where possible. Some suppliers provide warranties or installation support, which adds confidence in the product and the service you receive.

If you need help sourcing genuine parts, trusted outlets and brand pages often provide secure distribution channels. For assistance with sourcing and fitting injectors, you can reach out to reputable service providers who list Bosch parts as part of their inventory.

Australian petrol quality varies by region; using higher‑quality fuel with proper detergent packages helps reduce deposits. Where available, choose fuels that meet the octane and detergent specifications recommended by the vehicle maker. For owners in regions with lower detergent levels or who drive mostly short urban trips, more frequent inspection or scheduled maintenance is prudent to prevent build‑up.

For older vehicles converted to run on alternative fuels or for those operating in rural areas with variable fuel supply, consult with a mechanic about filtration upgrades, more frequent filter changes and injector inspection intervals.

Tuning an engine with direct injection requires careful consideration of injector flow rate and spray pattern. Upsized injectors must be matched with ECU remapping and, often, higher fuel rail capacities and upgraded high‑pressure pumps. Bosch offers performance injector options but when increasing fuel delivery for forced induction or higher power levels, tuning shops typically recommend a full fuel system review: rail, pump, lines and ECU maps.

Failing to match injectors and tuning properly can cause lean conditions under load, risking engine damage. Work with reputable tuners who understand the implications of direct injection and use injectors that provide stable flow and spray characteristics under elevated pressure and temperature.

When buying replacement injectors, look for part compatibility and ask for flow test data. Keep installation simple by replacing seals and related components at the same time to avoid future leaks. Insist on a post‑install road test and, if available, a short data logging session to verify stable fuel trims and absence of misfires. Where your workshop offers warranty on parts and labour, retain paperwork — it often proves invaluable if a later issue emerges.

If you need a local supplier, many reputable vendors stock Bosch injectors and can advise on fitment. For assistance with sourcing and installation, contact recognised service providers who specialise in fuel systems.

In case you want to explore specific injector options or confirm fitment for your vehicle model, our team can help; feel free to use Contact us to arrange advice or a vehicle inspection.

High pressure in GDI systems makes them inherently dangerous to service without proper tools and training. Always relieve system pressure before disconnecting components and never attempt injector removal with the ignition on or the fuel pump running. Use appropriate eye protection and gloves, and follow vehicle maker procedures for isolation and system bleeding. If you are uncomfortable performing high‑pressure fuel work, seek trained technicians to avoid injury or damage.

Bosch GDI Fuel Injectors deliver fuel directly into the combustion chamber under very high pressure, enabling finer metering, multiple injection events and higher compression operation. Port injectors spray into the intake port where the fuel helps keep the intake valves cleaner because fuel washes over them.

With good fuel and proper maintenance, Bosch injectors generally meet or exceed typical service life expectations of 150,000 to 300,000 kilometres, though this varies with driving style, fuel quality and maintenance history.

Basic additive cleaners are available for fuel tanks, but meaningful restoration of GDI injectors usually requires bench ultrasonic cleaning and flow testing at a workshop. Electrical faults or severe mechanical wear need replacement.

Use high‑quality fuel with detergents, avoid excessive short trips, consider intake cleaning services as recommended, and, where the vehicle supports combined port and direct injection, ensure the system is functioning correctly.

Yes, but any change in injector flow capacity must be matched with ECU calibration, and often upgrades to the high‑pressure system. Work with experienced tuners and use injectors rated for the operating pressures and temperatures your build requires.

Bosch Fuel Injectors play a pivotal role in unlocking the benefits of gasoline direct injection: improved fuel economy, stronger torque, reduced emissions and sharper response. Choosing genuine Bosch GDI injectors and following correct diagnosis, maintenance and installation practices preserves engine performance and emission compliance over the long term. For owners and workshops across Australia, replacing or servicing injectors with parts that match OEM specifications avoids common problems such as misfires, poor fuel economy and particulate issues. If you need parts, professional advice or installation support, reach out to our team — Quickbitz can help you source the right Bosch components and get your vehicle running at its best.