Common Types of A...

Dec 03, 2025

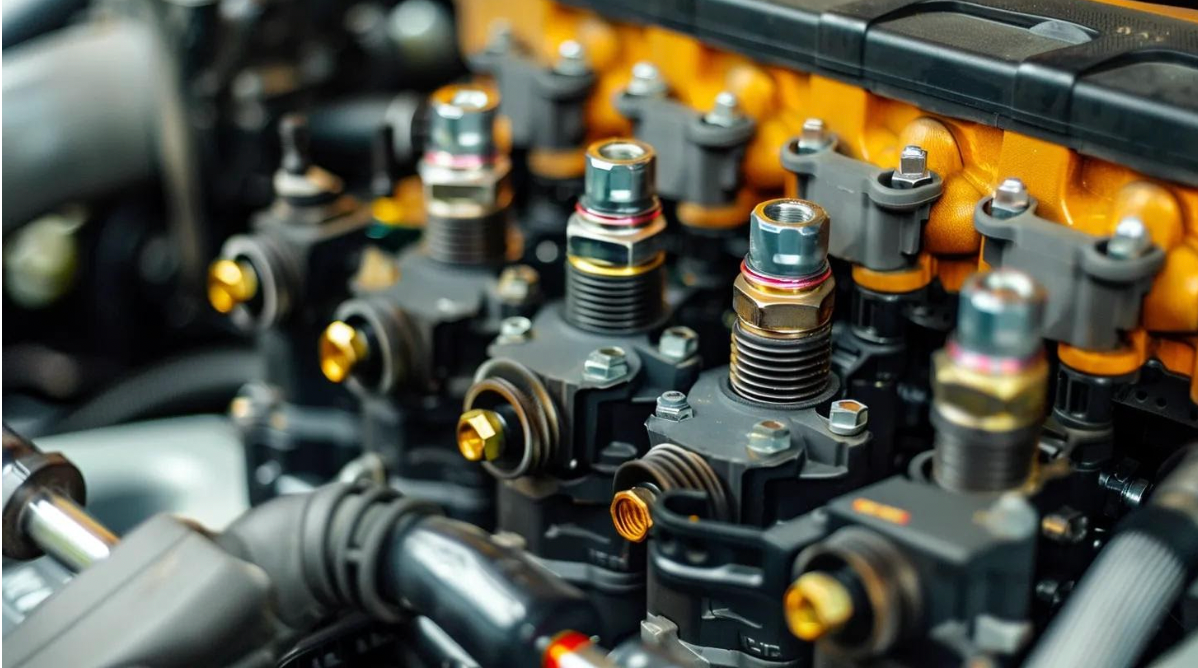

The moment you start your engine and hear it settle into a smooth idle, you’re hearing the result of countless tiny engineering decisions working together — and the fuel injector is one of the most critical components in that orchestra. Bosch Fuel Injectors deliver precise fuel metering, rapid atomisation and consistent spray patterns that directly affect throttle response, emissions and long-term engine health, making them a compelling choice for drivers who expect reliable performance from their vehicle. In this article I’ll unpack the technical benefits and real-world gains of choosing genuine Bosch components, explain how they interact with modern engine control systems, and show why fitting authentic parts is an investment in efficiency, longevity and peace of mind.

Bosch has long been synonymous with automotive precision engineering, and this reputation comes from rigorous research, strict manufacturing tolerances and continuous product validation across a wide range of engines. Genuine Bosch Fuel Injectors are designed to match the original equipment manufacturer (OEM) specifications for flow rate, spray pattern and electrical response, which means they integrate seamlessly with the engine’s electronic control unit and sensors. That compatibility reduces the need for ECU remapping, avoids fuel trim compensation issues and preserves the delicate balance between air, fuel and ignition timing that modern engines rely on.

When fuel injectors deliver the exact amount of fuel at the precise time required, combustion becomes more efficient. Efficient combustion translates to better fuel economy and lower tailpipe emissions, outcomes that matter for both running costs and environmental regulations. Bosch’s stringent quality control also minimises variation between injectors, so multi-injector banks remain balanced and the engine runs smoothly across all cylinders. In contrast, lower-cost aftermarket injectors may have inconsistent flow or spray characteristics, which can cause rough idling, elevated particulate emissions and uneven cylinder wear. You can find more information about these systems in our taking care of your vehicles fuel injector article.

Bosch’s development processes include dynamic flow testing and long-term endurance cycles that mimic real-world conditions. This testing reduces the likelihood of premature failure from common causes such as clogging, nozzle wear or electrical degradation. When you choose a genuine Bosch injector you get parts engineered for the thermal and chemical stresses unique to your vehicle, not just a generic fitment that “sort of” works.

Bosch injectors contribute to engine efficiency through superior atomisation, tight response times and accurate metering. Atomisation is the process of breaking liquid fuel into tiny droplets so that it mixes uniformly with incoming air. Superior atomisation increases the surface area of the fuel exposed to oxygen, enabling faster, more complete combustion. This not only increases power output per litre of fuel but also reduces unburned hydrocarbons and soot formation.

Precise electrical control in Bosch Fuel Injectors means that the valve opens and closes with predictable timing and duration, giving the engine’s ECU a consistent baseline from which to fine-tune timing and mixture. The result is more stable idle characteristics and smoother transient response when accelerating or decelerating. In turbocharged engines, where air density changes quickly, this consistency is crucial to avoid lean or rich spikes that harm performance and may stress exhaust after-treatment systems.

Bosch’s injector designs also reduce drip and leakage during shutdown, avoiding fuel pooling and fouled spark plugs on restart. This behaviour improves cold-start performance and contributes to lower hydrocarbon emissions in short trip cycles, which are common in city driving and a key consideration for emissions testing regimes.

When fitted and calibrated correctly, genuine Bosch Fuel Injectors deliver noticeable gains in several everyday performance areas. Drivers typically experience improved throttle response, where the engine reacts more immediately to accelerator inputs, and a smoother power delivery across the rev range. This results from better atomisation and matching injector flow characteristics between cylinders.

Fuel economy gains are often modest on their own, but when combined with improved combustion consistency they become meaningful over time. For vehicles suffering from degraded or mismatched injectors, replacing them with Bosch originals can restore lost efficiency and shave fuel costs noticeably. Additionally, exhaust emissions become cleaner, which helps modern catalytic converters and particulate filters operate as intended, reducing the frequency of warning lights and costly after-treatment repairs.

Bosch injectors are built to maintain spray quality over prolonged service intervals, so these performance advantages are not just immediate but sustainable. For diesel owners, the precision of Bosch diesel injectors also reduces white smoke on cold starts and improves torque delivery at low engine speeds, which is advantageous for towing and heavy-load applications.

The injector does not operate in isolation; it is part of a larger fuel delivery and engine management ecosystem. Genuine Bosch Fuel Injectors work harmoniously with the fuel pump, fuel rail, pressure regulator, fuel filter and the engine’s ECU. Because injectors influence the effective air–fuel ratio, they also affect downstream systems such as catalytic converters, diesel particulate filters and oxygen sensors.

High-quality injectors reduce contaminant load downstream, which helps catalytic converters and particulate filters last longer and maintain efficiency. They also reduce the frequency of misfire events that can trigger fault codes and limp-home modes. For turbocharged engines and direct-injection systems, consistent injection timing preserves combustion chamber cleanliness and reduces the likelihood of carbon build-up on intake valves and pistons.

Routine maintenance items like fuel filters and fuel quality remain important, but starting with a genuine injector reduces the risk that a single component will cause cascading faults or premature wear elsewhere in the fuel system. Mechanics appreciate this reliability because it simplifies diagnostics and reduces repeat visits for the same problem.

Bosch invests in materials engineering and tight assembly tolerances to ensure longevity. Components such as the injector pintle, nozzle plate and internal seals are manufactured to resist erosion from high-pressure fuel and chemical attack from modern petrol and diesel blends that include bio-components. This durability means Bosch injectors maintain their calibration over longer intervals, reducing the need for frequent replacements or flow-matching procedures.

Testing under accelerated conditions simulates thousands of hours of service to identify failure modes before products reach customers. That engineering maturity translates to fewer warranty returns and a more predictable service life for vehicle owners. The result is fewer unplanned breakdowns and lower total cost of ownership over the life of the engine.

Modern emission standards are exacting, and achieving compliance depends on precise control of combustion chemistry. Genuine Bosch Fuel Injectors enable stable stoichiometry and minimise transient-rich or transient-lean conditions that exacerbate NOx or particulate formation. By ensuring consistent injection volumes and timing, Bosch injectors help emission control devices operate within their design windows, reducing the risk of exceedance.

For diesel engines, clean atomisation reduces soot and helps diesel particulate filters regenerate more predictably, which lowers the risk of clogging and associated exhaust back-pressure issues. For petrol direct-injection engines, Bosch injectors help control particulate emissions that have become a focus for regulators worldwide. In short, fitting authentic injectors is a practical step toward meeting regulatory requirements, and it reduces the environmental footprint of everyday driving.

Replacing injectors with genuine Bosch units is only part of the equation; correct installation and, where necessary, ECU calibration are essential to reap the full benefits. Many modern vehicles require the ECU to adapt to new injectors by running set adapt procedures or, in some cases, applying calibration files to ensure optimal fuel trims and timing. Workshops experienced with Bosch products understand these requirements and will verify injector resistance, flow rates and electrical connectors.

Diagnostics are simplified when using genuine injectors because Bosch parts tend to conform tightly to expected electrical signatures and flow curves, making deviations easier to spot during testing. Technicians can then make targeted repairs rather than performing broad and costly system replacements. Proper sealing with OEM-type O-rings and torqueing the injector hold-downs to the manufacturer’s specification prevents fuel leaks and vacuum losses that otherwise compromise performance.

Bosch designs injectors to be compatible with a wide range of modern fuels, including E10 blends and diesel fuels containing biodiesel components. Their materials resist swelling and degradation that could affect sealing surfaces, which is especially relevant in regions where fuel compositions vary seasonally. This compatibility reduces the incidence of injector-related fuel system problems and maintains consistent performance across different fuel qualities.

|

Attribute |

Genuine Bosch Fuel Injectors |

Generic aftermarket injectors |

|---|---|---|

|

Flow consistency |

High |

Variable |

|

Spray pattern precision |

Engineered to OEM spec |

Often generic |

|

Endurance testing |

Extensive |

Limited |

|

ECU compatibility |

High |

May require remapping |

|

Warranty and support |

Manufacturer-backed |

Varies by supplier |

The benefit of choosing Bosch injectors is particularly evident in high-mileage engines where original injectors have drifted from their flow specifications. Owners reporting rough idles, poor cold starts, or intermittent misfires often find that replacing suspect injectors with Bosch units restores smooth performance and reduces engine diagnostic trouble codes. Likewise, performance enthusiasts who modify induction or boost systems see a stable and predictable base when they upgrade to Bosch injectors, which supports further tuning work without unexpected injector-related anomalies.

Commercial fleets and heavy-duty applications gain value from Bosch injectors through lower downtime and predictable maintenance intervals. For trucks, utes and towing vehicles, injector durability and consistent low-end torque can yield measurable productivity improvements over a fleet’s operating cycle.

Regular fuel filter replacement and the use of quality fuel are simple, effective ways to prolong injector life. Periodic use of approved injector cleaners can help dissolve varnish and carbon deposits that impair spray patterns. For direct-injection petrol engines, occasional professional cleaning or walnut blasting of intake ports may be necessary to remove carbon build-up indirectly influenced by injector behaviour. When replacing injectors, always use new sealing components and follow the torque and installation procedures laid out by the vehicle manufacturer.

Selecting the correct Bosch Fuel Injector depends on vehicle make, engine code and intended use. OEM reference numbers and flow-rate tables are essential to ensure the injector will match the engine’s fuel demand at peak power and idle conditions. Bosch’s product portfolio spans standard OEM replacements to high-flow performance variants, giving owners flexibility depending on whether the priority is factory-correct behaviour or modified-engine demand. When in doubt, consult manufacturer documentation or a qualified technician to verify part numbers and calibration requirements.

Within service environments, workshops often keep Bosch injector part-number cross-reference tools at hand to prevent mistakes. Professional installers also check fuel pressure and rail condition when changing injectors because a weak fuel pump or a clogged rail can confound injector performance assessments even with genuine parts fitted.

Genuine Bosch Fuel Injectors are typically more expensive than cheaper aftermarket options, but the extra cost must be weighed against the savings from fewer diagnostic headaches, longer service life and optimised fuel efficiency. When factoring in potential repair avoidance — such as preventing catalytic converter damage or avoiding repeated misfire repairs — the total cost of ownership often favours genuine parts. For drivers who keep vehicles long-term, the investment in Bosch injectors frequently pays dividends in reliability and lower lifetime maintenance.

A common misconception is that all injectors of the same physical size and connector will perform identically. In reality, internal hydraulics, nozzle geometry and electrical characteristics define each injector’s behaviour. Another myth is that cleaning alone will always restore an injector to OEM performance; while cleaning can help remove deposits, it cannot reverse erosion or mechanical wear of internal components. Choosing genuine Bosch Fuel Injectors removes much of the guesswork because their documented performance curves and material selection are known and repeatable.

For owners seeking power upgrades, Bosch offers performance-grade injectors that provide higher flow rates while maintaining precise atomisation. Upgraded injectors should be paired with corresponding fuel-pump upgrades and ECU tuning to ensure the air–fuel ratio stays within safe limits. Properly matched, Bosch performance injectors allow tuners to increase power safely without introducing erratic drivability or risking engine damage from lean conditions.

Yes. Bosch injectors offer durable materials, precise spray patterns and consistent flow which reduce long-term maintenance and support reliable engine performance.

Replacement intervals depend on fuel quality and driving conditions, but genuine injectors commonly last longer than cheaper alternatives; regular checks during major service intervals are recommended.

Cleaning can help remove deposits but will not fix mechanical wear or erosion; professional flow testing will determine whether replacement is necessary.

Most OEM replacements do not require remapping, but performance upgrades or significant flow-rate changes will need ECU calibration to maintain correct fuel trims.

Symptoms include rough idle, misfires, higher fuel consumption, fuel odour, and illumination of the check engine light.

Bosch Fuel Injectors offer precise engineering, durable materials and consistent performance that together support improved combustion, lower emissions and greater engine reliability. Choosing genuine Bosch injectors reduces diagnostic uncertainty, helps downstream systems operate correctly and preserves the intended behaviour of modern engine management systems. For everyone from daily commuters to fleet managers and performance enthusiasts, the long-term value of authentic parts is clear: fewer surprises, lower overall repair costs and steadier engine efficiency. If you’re looking for professional supply and fitting of genuine Bosch injectors, Quickbitz provides verified parts and expert service to ensure your engine performs as it should.